A professional kitchen is one of the most demanding work environments for clothing. Chefs spend long hours moving quickly, kneeling by low ovens, and navigating tight spaces. The last thing any chef wants is a pair of trousers Continue Reading

Notes From the Coast: What I Learned About Style by Letting Go

There’s a strange kind of clarity that only comes from being far away from your wardrobe. Not the edited rack you reach for Monday through Friday—the one with the crisp shirts and dependable denim—but the rest of it. Continue Reading

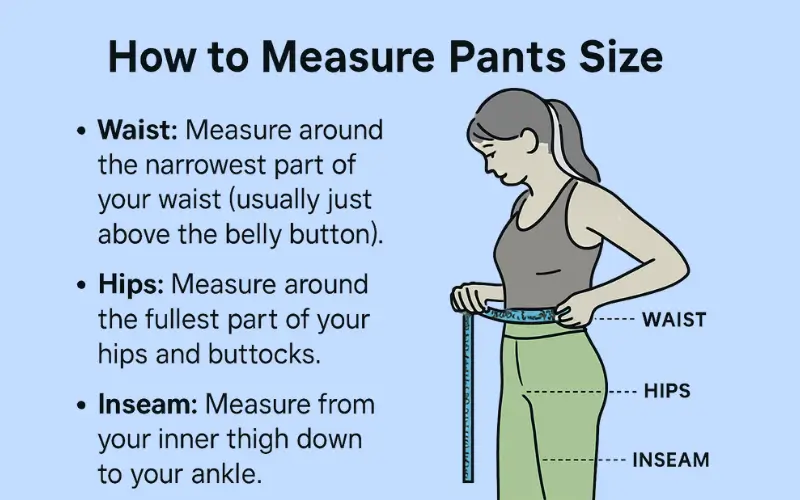

The Ultimate Women’s Pants Size Calculator & Fit Guide

Finding the perfect pair of pants can feel like a fashion guessing game. One size fits in one brand but feels tight in another. You might be a size 6 in the US, an 8 in the UK, Continue Reading

How to Prepare for Your First Wedding Dress Appointment

Your first wedding dress appointment is one of the most exciting parts of the planning process but it can also feel a little overwhelming. With so many styles, designers, and options available, walking into a bridal boutique unprepared Continue Reading

Dainese – Armor for the Asphalt-Born

If you’re into motorcycle racing or long-distance touring, there’s a good chance you’ve heard of Dainese. This Italian brand has become a symbol of performance, safety, and high-quality gear for bikers all over the world. Whether you’re leaning Continue Reading

How to Style Preppy Outfits for Every Season

Understanding the balance between comfort and refinement helps you master how to style preppy outfits for every season with ease. Adopting classic, year-round clothing is essential to mastering preppy style. Preppy ensembles are elegant and adaptable for any Continue Reading