Introduction

The textile industry, a multifaceted sector, relies extensively on intricate processes that demand precise temperature control. In this comprehensive guide, we will delve into the fundamental role of boilers and thermal oil heaters within this industry, including the technical aspects. We’ll explore different types of boilers used, the applications of thermal oil heaters, the necessity of boilers in the apparel industry, the reasons for the requirement of thermal oil heaters, and delve into the technical intricacies of how these heaters function.

Textile Industry and Its Heat-Dependent Processes

The textile industry is a complex ecosystem where raw materials undergo transformation into a vast array of fabrics and garments. Multiple stages in this journey necessitate controlled heat application. These processes include dyeing, printing, drying, and finishing. To facilitate these operations, boilers and thermal oil heaters are indispensable.

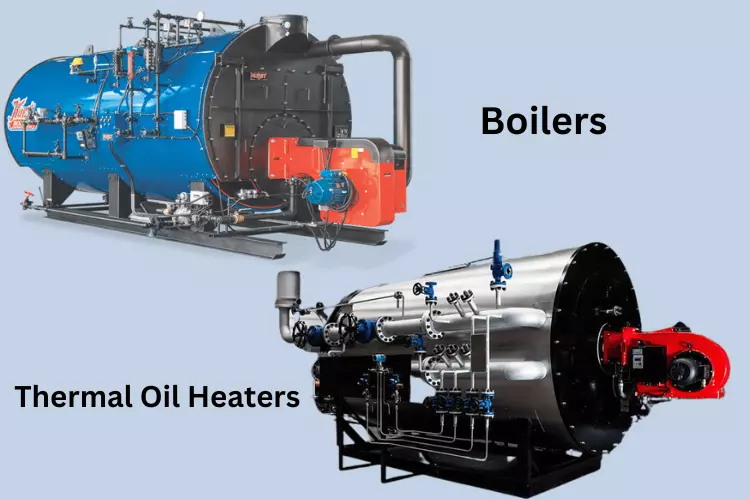

Importance of Boilers and Thermal Oil Heaters

Boilers and thermal oil heaters serve as the thermal energy backbone of the textile industry. They ensure the consistent and precise delivery of heat to various stages of production. Let’s explore the different types of boilers used in more technical detail:

Steam Boilers

Steam boilers are the workhorses of the textile industry. They operate by combusting fuel, typically natural gas or oil, to produce high-pressure steam. This steam is then utilized in heat exchangers to transfer thermal energy to the target processes, be it water, air, or other fluids.

Hot Water Boilers

These boilers generate hot water through a similar combustion process as steam boilers but operate at lower temperatures. They are ideal for applications where a lower heat threshold is required.

Thermal Oil Boilers

Thermal oil boilers employ thermal oil as the heat transfer medium. Thermal oil, typically a synthetic or mineral-based fluid, offers precise temperature control and is pumped through a closed-loop system. The fluid is heated through combustion of fuels and then circulated through heat exchangers to transfer heat to the process equipment.

Why Boilers are Necessary and How Thermal Oil Heaters are Applied in the Apparel Industry

In the textile industry, both thermal oil heaters and boilers play indispensable roles in various critical processes. Here’s an integrated view of how these heating systems are applied:

Dyeing

Thermal Oil Heaters: Thermal oil heaters play a pivotal role in maintaining precise temperatures in the dye bath, ensuring uniform distribution of dye molecules across the fabric.

Boilers: Achieving consistent and vibrant colors in textiles requires precise temperature control, which boilers provide during the dyeing process.

Printing

Thermal Oil Heaters: These heaters are employed to maintain precise temperatures on printing rollers, enabling consistent and high-quality ink application to textiles.

Boilers: Accurate heating is crucial to maintain the quality of printed designs, ensuring they adhere perfectly to the fabric.

Drying

Thermal Oil Heaters: After dyeing or printing, fabrics need to be dried efficiently and evenly. Thermal oil heaters provide the necessary heat for efficient drying processes.

Boilers: Boilers enable efficient and uniform drying of fabrics post-dyeing or printing.

Finishing

Thermal Oil Heaters: Thermal oil heaters are instrumental in heating the finishing chemicals. This is crucial for achieving desired properties in textiles, such as wrinkle resistance or softness.

Boilers: To impart desirable properties to garments, boilers are essential for heating finishing chemicals.

Why Thermal Oil Heaters are Required in the Textile Industry

Thermal oil heaters are vital in the textile industry for several technical reasons:

High Temperatures: Certain textile processes, like heat-setting, demand precise and sustained high temperatures, which thermal oil heaters can efficiently provide.

Safety: Thermal oil is non-flammable, offering a high degree of safety, especially in comparison to traditional steam boilers that operate under higher pressures.

Longevity: These heaters have a prolonged lifespan, largely due to the absence of water-related corrosion issues, making them a cost-effective investment for textile manufacturers.

Ease of Maintenance: Thermal oil heaters are technically straightforward and easy to maintain, reducing downtime and ensuring uninterrupted production.

How Thermal Oil Heaters Work

Thermal oil heaters function through a technical yet straightforward process:

- Fuel Combustion: Natural gas or oil is burned in a combustion chamber, heating a coil or tube bundle containing thermal oil.

- Heat Transfer: The heated thermal oil is then circulated through a heat exchanger, where it transfers its thermal energy to the process fluid. This efficient heat transfer is facilitated through a closely controlled temperature differential.

- Temperature Control: The process fluid, now heated to the desired temperature, is ready to perform its role effectively in textile processes.

Conclusion

Boilers and thermal oil heaters are the heartbeat of the textile industry, providing precise and efficient heat for processes ranging from dyeing to finishing. Their technical specifications ensure safety, longevity, and cost-effectiveness in textile manufacturing, making them indispensable tools for textile manufacturers seeking to optimize their production processes. Understanding the technical intricacies behind their operation is fundamental to unlocking the secrets of the textile industry’s success.