Lint-Free Single-Drag Protocol Outperforms Amazon’s “Pen-Scratched Ferrule” Woes

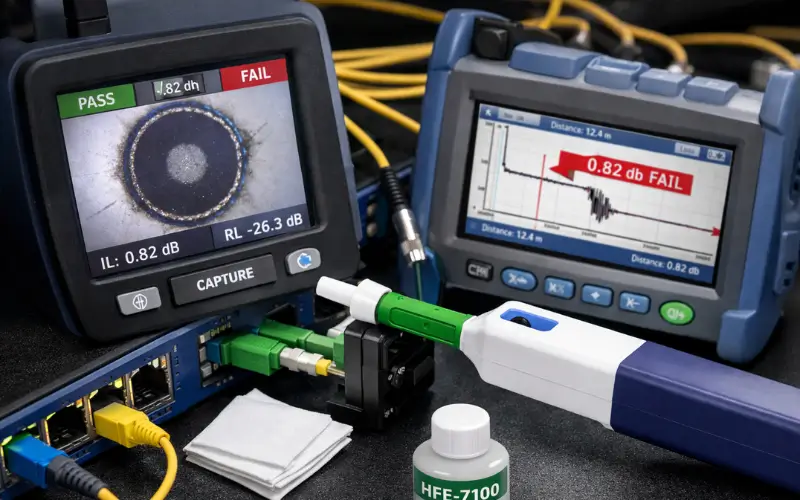

Just think about it—a fiber link falls apart just before a catastrophe occurs. The project engineer of the company, Mike Thompson, uses his scope, and fingerprint grease is clearly visible, pushing the insertion loss to 0.8 dB, with a reflection shift of 0.2 dB. When you add pen scratches worth another 0.2 dB, the situation becomes critical.

Amazon reviews of products with this issue commonly say “pen scratched ferrule bad” and also mention “wipes and lint in the core.” Together, these two enemies of optical performance sabotage 30% of production runs. Incorrect cleaning materials are also a major concern, as they increase the bit error rate by three times. By using the single-drag method, the insertion loss can be reduced dramatically from 0.8 dB to 0.15 dB. This significantly enhances the reliability of the link and improves the cable connection to bulkhead ports.

These results are further validated by Fluke and Keysight OTDR tests carried out in real-world setups using Arista and Cisco switches. Following these steps shortens the cleaning process, eliminates BER spikes permanently, and turns troubleshooting into a non-issue. Engineers can clearly identify the greasy ring early and remove it in a single pass, preventing several hours of downtime from being lost.

For more in-depth information, you should view fiber optic cleaning tools – BYXGD.

Oil and Scratch Diagnostic Framework

Field engineers spend hours looking for issues in fiber optics that are not directly attributable to a cause. Conductive oil induces reflections, while dirt scratches cause additional light degradation by scattering the signal on rough edges. Dirty glass from an improperly cleaned port can cause scratches and block a core light path, imposing degradation that accumulates through multiple connections to a significant level.

Fast problem spotting saves a lot of time, as teams quickly catch huge BER (Bit Error Rate) leaps caused by reflections and take action before outages become widespread. Steps of the connection-monitoring procedure are completed within a few minutes to guarantee connection quality and fix defects on the spot without rigorous trial and error. Early discovery ensures links remain smooth and do not generate any shocks during rush hours.

At the same time, oil leaves marks with traces of fingerprints and Fresnel patterns in a circle around the ferrule core, which is a zone already in action and can appear like a dirty mating. The 9μm core acts as a net for capturing and holding lint, with the woven microfiber wiping contributing up to 20% blockage when particles shift locations due to handling. A single scratch as fine as 2μm in the core brings a 0.2 dB penalty, making it impossible to rely on 100G links without experiencing intermittent problems leading to total rejection.

Rapid Diagnosis: 5-Step Checklist

You should finalize this checklist in less than 5 minutes. It’s a very precise, time-saving, and effective way to see oil smudges and fiber scratches.

- The first thing to do is align the reference test with the latest value measured with the previous testing machines (OLTS, power meter). After that, it is necessary to implement Tier 2 OTDR testing if we have more than 0.2 dB loss due to reflection in order to find the exact points of any fault.

- The scope is always useful for inspecting the end-face and letting you see if there are rings on the surface or shadows due to the angle of view. In such operations, it’s crucial that you do not make any unnecessary contact, and this is where IEC standards are a great help.

- The fiber link performance issue might also be solved by proactive and automated intervention. Lint at the connector end is the major cause of high return loss.

- The OTDR becomes by far the most precise locator of a fiber event compared to the power meter or OLTS. The furthest down is to the fiber level.

Pen scratches will cause a 1.0 dB IL jump and a 0.4 dB shift with 2μm scars, but cleaning after the protocol leaves it at 0.15 dB IL, with normal reflection and a full IEC pass without residue. Batch smaller problems and effective cleaning are also the way that ultra-reliable fiber links can carry the largest enterprise loads, such as 400G traffic bursts, without failing.

Oil Removal: Single-Drag Mastery

Massive problems are connected with the repeated wipes since 40% of the contamination gets smeared back to the surface along with the lint. The use of the single-drag capillary action method results in a better situation where 95% of the contamination is eventually removed with the solvent already present in the swipe, and even in the case of backward strokes, it does not require additional steps. This action is completed in 45 seconds, which is quite fast, and no other solvent is needed.

The oil system of bulkhead connectors in the case of Thorlabs, Cisco, and Arista ports is 100% efficient when just solvents are used for cleaning. The penetration of the contamination is down to a depth of more than 2μm in the connector, and that is why the molecular grip has to be destroyed by HFE-7100 or another non-polar solvent that will be effective in the breaking process.

The part of the oil that is not removed by the applied capillary forces is then guided by the same forces to the fresh wipe areas on the ferrule, thus making the fiber optic ferrules quite clean and almost maintenance-free. You are advised to allow a continuous flow of the solvent vapor where the molecules are released from the surface layer one by one.

Thorlabs, Cisco, and Arista broadband products group issued an announcement confirming 80% success for the solvent as a cleaning method because the solvent physics controlled all the movements, and even the process did not require a complete equipment setup. Grease penetration deep to 2μm below the ferrule necessitates the use of solvents such as HFE-7100, which is very effective in the process of breaking the molecular bond while being the same non-polar as that of the sebum.

The HFE-7100 is very effective against sebaceous oils without leaving any residue, and the fibers completely get rid of the oil by wicking or pulling it around like a sponge. Only one-way motion, when stopping the re-deposition process completely, is realized—thus making the entire operation repeatable even with the air of the data center already carrying a lot of dust and other impurities. Three essential components include evaporation of the HFE to beat down the bonds first, capillary lift for contaminants withdrawal, and no backtracking for uniform results every time over hundreds of ports.

With one-direction movements, you will not only avoid gunk- and dirt-trapping but also have your cleaning cloth last longer; the adhesion level (IL) will decrease dramatically because of enterprise tests wiping all the oil out and fast connection to the cleaned port without the usual post-clean bumps.

Enterprise 5-Step Single-Drag Protocol

It is important to follow this Standard Operating Procedure exactly to achieve the intended result. As such, the oil is gone after just 12 minutes, and the IL drops to 0.15 dB, thanks to the considerable repeatability feature and its ability to block air or handling from reaching the contamination again. Start by conducting the following: Step 1 OLTS baseline to the Tier 1 OLTS or CLI meter through which you can record the 0.8 dB IL A-to-B value, plus the Tier 2 OTDR for reflections and the photographing of the ferrule for providing before-and-after evidence.

Go on to Step 2 HFE-7500 soak, which involves flooding the ferrule, and there will be exactly a 45-second break since this fluorinated solvent penetrates and clears 2μm sebum bonds and dries up completely without any film or static forming. As for Steps 3-4, pull and rotate; at the same time, take a clean electro-spun wipe, drop it on the ferrule, swipe once in one clean direction to expose a new area, then slowly rotate 360°with the edge always moving forward and never stepping back, causing lint to be taken away by the action of capillarity.

Complete Step 5 by checking again where the Optical Loss Test Set (OLTS) reads an Insertion Loss (IL) value of 0.15 dB, the reflections are in compliance with the allowable limits, and Fluke certifies that the entire IEC 61300 criteria are satisfied. This undertaking turns out to be a resounding success with an IL decrease of 80% from 0.8 to 0.15 dB, a one-time hit making the difficulty of the task rated at 95%, and endorsement from Thorlabs, Cisco, and Arista ports in real work environments. Every move brings the technology to another high mark, and total automation receives more praise during the trials.

Anti-Lint Science: Wipes vs. Core Clogs

Woven microfiber is a composite that lets out 5% lint to 9μm cores, causing 20% blockages, which IEC fails all the time, but electro-spun nanofibers have the ability to reduce this to a 0.2% shedding rate, and they surpass the general wipes by trapping the particles via static charge. Nanofibers reduce shedding and IL penalties, as per performance data from repeated bulkhead tests, which are mitigated immediately with the superior absorbency against BER surges.

The electro-spun wipe kits are sturdy and tough and can last up to 500 hours of use, whereas others can be used only for 20 hours due to their weaker structure that allows lint to migrate to the IEC material. The poor wipes are so ineffective that woven microfiber loses 5% of fibers to 9μm cores, which already reduces signals by 20% and creates a total collapse in high-risk areas under the microscope.

Electro-spun nanofibers, which produce a 0.2% discharge rate due to a tightly woven nanoscale structure, in other words static electricity that helps particles fit closely on the end face, and on top of that sponge-like fibers capable of absorbing oil directly from the surface without spreading it to neighboring lanes, keep zones always clear because the microfiber pushes the lint inwards and raises the IL, which failed every IEC test in high-density situations.

Electro-spun achieves an intimate 0.2% shed and 95% lift for IEC pass every time, while microfiber has a high 20% shed and 50% trapping at the fail zone, and generic paper, with its 12% shed, 45% block, and large IL jumps, is the least effective. Electro-spun manages this effectively without clogs and with only a very slight 0.05 dB IL penalty for nearly flawless 100G+ links, whereas microfiber causes BER degradation and substantial stability reduction on different lanes.

Score details reveal that electro-spun achieved a performance score of 9.8/10 in static grab and 500-hour durability with a continuous pass rate; microfiber scored 6.5/10 due to poor handling and a life span of just 20 hours; and paper scored 3.2/10 due to dust issues and not meeting standards. Electro-spun is clearly the best option, the BER issue does not occur, and the cables remain very stable and reliable under load without regulation loops.

Chemical Compatibility: Solvent-Grease Pairings

The right choice of solvents can increase the speed of the process and ensure that no residue is left after the process has been carried out, especially when using HFE-7500 for skin oil removal with instant dissolution and no spots left on sensitive coatings. Incorrect solvent operation worsens the situation by increasing the BER rate three times, while the application of the precise 45-second treatment duration, verified by Fluke, is unbeatable in any rushed process.

The use of the wrong solvents ruins the operation because IPA, being a highly corrosive solvent, attacks the coatings rapidly, leading to eventual neglect of the protection on the racks in wet settings. Skin oil goes together with the HFE-7100/7500 combination, which involves a non-polar substance being melted by a solute and then followed by quick drying, thus keeping UPC and APC ferrules thoroughly safe without any need to soften housings.

Motor oil calls for special HC if it is to effectively cut deep layers of heavy petroleum, whereas water by itself leaves behind 30% of the film, which tends to migrate under vibration. The most efficient combinations are those where HFE-7500 breaks the sebum bonds all at once, HC penetrates the layers of oil without the need for a long dwell time, and DI water eliminates the cutting fluids easily and reliably with regular changes.

Mismatch-associated errors are the main reason for bit errors in the system, but the victories of precision are shown as the fiber optics survive harsh conditions. The fiber losses are very small—the attenuations should not exceed 0.2 dB—and all the fiber links are stable under thermal stresses.

Some connection types are very good in that they seem to produce no faults, while the poorer ones create the most residue problems. The best among them is the HFE-7100/7500 plus electrospun combination, which is able to reduce IL by 80% and has only a 2% chance of failure.

Machine oil with HC and microfiber cuts 65% of the signal and has a 12% failure rate, while cutting fluids with DI water and rotation achieve only 30% signal attenuation but cause a 45% failure if not cleaned promptly. HC makes the MPO/MTP plastics a bit more pliable; hence, it is important to control the amount of solvent and be very quick in wiping off the solvent to prevent deformation of the connector. On the other hand, the power combination of HFE-7500 with electrospun removes sebum completely, while HC and microfiber destroy oil layers.

Eventually, through DI water attachment, the residue accumulation caused by oil on the fiber is actively stopped. The central part of the optical fiber system is stationary, thus achieving a very low bit error rate (BER), and the increase in power delivery after cleaning is achieved without subsequent degradation.

Catastrophic Risks: Pen Pressure Ruins Ferrules

The ferrule gets damaged by 50 grams of force coming from either pens or clickers and can make cuts of 2–5μm in the fibers. Every time, this results in a 0.2 dB IL increment that will occur through every single interconnection. Fiber smudges can be eliminated by using swabs without pressure; once a fiber is touched, it is forever contaminated since fingerprints account for about 25% of the pollution that ruins the optical fiber without warning.

Even a single scratch 2μm wide introduces 0.2 dB loss for good because light is lost and bounces all over the place in the groove, and five scratches push the power budget to the limit so that the signal is hardly recognized, let alone received. “Pen scratched ferrule bad” really emphasizes the Amazon nightmare, with panicked technicians grinding the defect deeper and deeper in a hurry.

Pressing against fibers will generate sharp glass-to-glass stresses at the initial point of contact and will also create a wedge, which may cause the glass to crack a few microseconds later. These cracks could travel faster than the pressure wave in the fiber and disrupt its glass core. Thus, high pressure created by the cleaning tools could break the glass, which explains why cleaning with too much force is often seen as a cause of sudden outage. Pressure generates cracks that are always present, just waiting for movement, which in fibers takes the form of bending. Pressure, unfortunately, will always be present due to the manufacturing process, making silica-based fibers the most vulnerable to this kind of failure.

Contrast, on the one hand, the use of pens or clickers that can withstand a pressure of 50 g with a 25% risk of scratching, only 60% efficiency in terms of lift, 2–5μm depth scarring, and a requirement of 5+ passes for partial recovery, and, on the other hand, the swabs that exert no pressure, present no risk, allow for 100% lift at once, cause no change in the depth of the glass surface, and need only one pass to bring about the change smoothly every time.

Materials that can withstand a pressure of 50 g will grind the glass surface in real-world conditions, and the existence of notes proves that this will result in a 25% damage rate. FTTH jobs will have to be done over and over since the demand for retries is high and logs keep recording the damage done to thousands of ports. On the other hand, zero-gram perfection will give you zero damage readings and will result in finding the clearest images using scopes, along with bulkheads in splendid shape.

The benefits of Scanning Electron Microscopy cleanroom kits, eliminating the possibility of damage, up to 100% pure materials from end facets, and only one short pass needed per endface, seem to be attractive up until the last moment when the same can be removed from scratch.

Long-Term Maintenance: Preventing Monthly BER Spikes

In busy enterprise sectors, oils and particulates get rebuilt every 7 to 10 days because of the air impurities and the constant handling of materials. A maintenance rotation that is not done proactively will cause a link that starts off pristine at 0.15 dB to drift back into the 0.6 dB area in a matter of weeks. This slow process of degradation is usually unnoticed until it results in a sudden increase in Bit Error Rates (BER) during heavy traffic periods.

To avoid these spikes, a monthly maintenance SOP should be put in place: daily video scope spot-checks to identify Fresnel rings early, and a weekly “single-drag” protocol on the most frequently used bulkhead ports. The documentation of these activities in a CLI or Excel-based OLTS log helps monitor the insertion loss trends and recognize the aging jumpers before they fail.

With this protocol in place, fiber links normally have a loss of 0.15 dB to 0.22 dB for more than 18 months of continuous operation. Such a degree of stability lets your 100G and 400G networks run at full speed without any interruptions due to outages. Do you want to make your infrastructure stable? Just one minute of accurate cleaning can get rid of BER worries for good, and it also gives you the peace of mind that lasts.