Silk is the most beautiful fiber of all textile fibers. Silk is acclaimed as the queen of textiles. Silk comes from the cocoon of the silkworm. To produce silk filament there requires a great deal of handling and processing. Silk is one of the most expensive fibers.

Production of silk from Cocoon

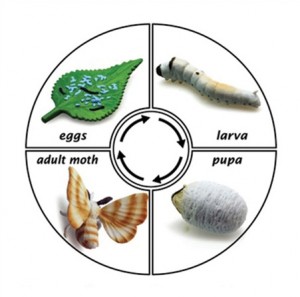

The production of cocoon for their filament is called sericulture. The life cycle of silkworm encircles in the four stages. i.e.

- The egg,

- The silkworm/larvae,

- The pupa/cocoon and

- The Moth.

The silkworm which feeds on mulberry leaves forms a covering around it by secreting a protein like substance through its hood.

Filature operation

The cocoons raised by the farmer are delivered to the factory is called a filature. In the factory, the silk is unwound from the cocoons and the strands are collected into skeins. Some cocoons are scientifically bred in such factories. The filature operations consist of the following stages.

Sorting

Cocoons are sorted according to the color, size, shape, and texture as these affect the final quality of the silk. Cocoons may range from white and yellow to gray.

Softening the servicing

Silk filament is a double strand of fibroin, which is held together by a gummy substance called to service or silk gum. After the cocoon has been sorted, they are put through a series of hot and cold immersions, as the service must be softened to permit the unwinding of the filament as one continuous thread.

Reeling the filament

Reeling in the process of unwinding the silk filaments from the cocoons and combining them together to make a thread of raw silk. As the filament of the cocoon is too fine for commercial use, three to ten strands are usually reeled at a time to produce the desired diameter of raw silk which is known as “reeled silk”. The useable length of the reeled filament is 300 to 600 m.

Bailing

The silk filament is reeled into skeins, which are packed in small bundles called books, weighing 2 to 4.5 kg. These books are put into bales weighing about 60 kg. In this form raw silk is shipped to silk mills all over the world.

Characteristics of silk

Silk is very strong in terms of tensile strength, meaning it can withstand a lot of pulling type pressure without breaking. This should not, however, be confused with wearability or abrasion resistance. Silk will not stand up to the heavy wear that other fibers will.

Silk can take on many different appearances. A raw silk fabric may fool you into thinking that it is cotton or synthetic. The more refined the silk and the smaller the yarn, the more it resembles the look and feel that we know as silky.

Like wool, silk is also a protein fiber. This gives many characteristics to its properties. It is sensitive to a range of chemical situations and cannot withstand prolonged exposure to either high alkalinity or to acid or oily soils. It becomes brittle with age and exposure to sunlight. If you are looking for silk sarees then you can have a look at best kanchipuram sarees.

How to identify silk

To identify silk we can do a burn test which is the best way to be sure if it is silk or not? Burning silk will leave powdery ash and will leave powdery ash and will extinguish itself when the flame is removed, just like wool. The easy way to tell silk and wool apart in the burn test is the smell. Where wool will have the smell of burning hair, the silk will have a much more disagreeable smell.