What is Corn Fiber: Corn fiber is the part of the corn that the body cannot digest. It comes from the outer layer of the corn kernel and is left over after corn is processed to make things like syrup or ethanol. Corn fiber is often used in animal feed, biofuels, or added to foods as a source of dietary fiber. Some types, like resistant corn fiber, help with digestion and are added to food to increase fiber without adding many calories. Corn fiber can also be used in the clothing industry to make eco-friendly fabrics, as it can be turned into a soft, breathable material called PLA (polylactic acid) fiber.

In the evolving world of sustainable fashion, innovations in textile production are reshaping how clothes are made—prioritizing environmental impact without sacrificing quality or style. One exciting development is the use of corn fiber, a renewable, biodegradable material derived from corn kernels and husks, as a raw material for textiles.

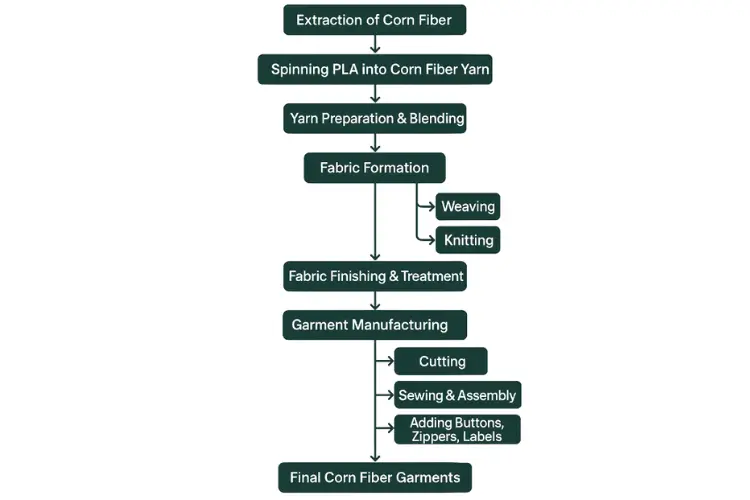

Corn Fiber to Fabric to Complete Garments Manufacturing Process

This article takes you through the fascinating journey of corn fiber—from its extraction and transformation into yarn, through fabric formation and finishing, to the final creation of garments. By understanding each step of this process, we gain insight into how modern science and traditional textile techniques come together to produce eco-friendly clothing options that meet the demands of today’s conscious consumers.

Extraction of Corn Fiber

The journey of transforming corn fiber into sustainable, wearable garments begins with the extraction of the fiber itself. Corn fiber is primarily derived from the byproducts of corn, including the kernels and husks, which are rich in natural components like cellulose and starch. Cellulose, a complex carbohydrate found in plant cell walls, provides the structural framework, while starch serves as a vital carbohydrate reserve within the plant.

The extraction process focuses on isolating corn starch, which is a crucial raw material for producing biopolymers. Through advanced industrial fermentation techniques, corn starch is converted into polylactic acid (PLA), a biodegradable and renewable biopolymer. PLA has gained significant attention in the textile industry as an eco-friendly alternative to petroleum-based synthetic fibers.

This biopolymer acts as the foundational building block for corn-based fibers. Unlike traditional fibers derived from fossil fuels, PLA fibers are sourced from renewable plant materials, making them a sustainable choice in reducing the environmental footprint of textile production. The extraction of corn fiber is not only a clever use of agricultural waste but also a step toward circular economy principles, where natural resources are utilized efficiently without excessive waste.

Spinning Corn Fiber into Yarn

Once polylactic acid (PLA) biopolymer is produced from corn starch, the next critical step is to transform this raw material into usable fibers that can be woven or knitted into fabric. The process used to convert PLA into fiber closely resembles the manufacturing of synthetic fibers such as polyester or nylon but with an eco-friendly twist.

First, the PLA biopolymer pellets are heated until they melt into a thick, viscous liquid. This molten PLA is then extruded through a spinneret—a device with many tiny holes—creating long, fine filaments. These filaments are rapidly cooled and solidified, forming continuous strands known as PLA fibers or simply corn fibers.

These fibers exhibit several characteristics that make them suitable for textile use: they are lightweight, biodegradable, and have good moisture-wicking abilities. However, to optimize the texture, durability, and comfort of the final fabric, PLA fibers are often blended with other fibers such as cotton or polyester. Blending enhances the mechanical strength and softness of the yarn, making the end garment more comfortable and long-lasting.

The spun yarns made from corn fiber can then be wound onto spools or cones, ready to be processed into fabrics through conventional textile manufacturing methods. This stage bridges the gap between raw biopolymer and the fabric that will ultimately be transformed into eco-conscious garments.

Yarn Preparation and Fabric Formation

After spinning, the corn fiber yarn undergoes preparation and fabric formation processes similar to those used for traditional textile fibers. These steps are essential for transforming the raw yarn into fabrics that can be tailored into garments.

Yarn Preparation:

The spun corn fiber yarn is carefully wound, cleaned, and sometimes blended further to ensure uniformity and strength. Proper tension and alignment during winding help prevent tangling and breakage in the subsequent weaving or knitting stages.

Fabric Formation:

There are two primary techniques to convert yarn into fabric—weaving and knitting:

- Weaving: This method involves interlacing two sets of yarns at right angles. The longitudinal yarns (warp) are held tight while the horizontal yarns (weft) are woven through them. Woven fabrics are generally strong and stable, making them ideal for structured garments or textiles requiring durability.

- Knitting: In knitting, yarns are looped together, creating a fabric that is more elastic and flexible than woven textiles. Knitted fabrics are breathable and comfortable, often used in casual wear and activewear.

Corn fiber fabrics inherit unique properties from their biopolymer origins. They exhibit excellent breathability, allowing air circulation to keep the wearer cool. Their natural composition also grants UV resistance, protecting skin from harmful ultraviolet rays, and moisture management, which helps wick sweat away from the body. Another vital benefit is biodegradability — when disposed of under industrial composting conditions, these fabrics break down much faster than synthetic counterparts.

This combination of comfort, functionality, and sustainability positions corn fiber fabrics as a promising material in the growing field of eco-friendly textiles.

Fabric Finishing and Treatment

Raw fabric made from corn fiber requires several finishing and treatment processes to enhance its aesthetic appeal, tactile qualities, and durability. These finishing steps ensure that the fabric not only performs well but also meets consumer expectations for comfort and appearance.

Eco-Friendly Dyeing and Printing:

One of the significant advantages of corn fiber fabric is its compatibility with sustainable dyeing techniques. Unlike conventional fabrics that often require harsh chemicals, corn fiber can be colored using eco-friendly dyes that minimize environmental impact. These dyes offer vibrant colors while reducing water pollution and chemical waste. Additionally, digital and natural printing methods can be applied to add patterns or designs without heavy chemical use.

Softness and Hand Feel:

To improve softness and the fabric’s tactile experience, sustainable finishing agents derived from natural or biodegradable sources are applied. These agents make the fabric feel smooth, lightweight, and pleasant against the skin, which is critical for consumer acceptance, especially in fashion and activewear markets.

Durability Enhancements:

Fabric finishing also targets the longevity of garments. Treatments that improve abrasion resistance, reduce pilling, and maintain color fastness help extend the life of corn fiber textiles. These enhancements reduce the frequency of garment replacement, supporting the broader goal of sustainability by lowering textile waste.

Functional Finishes:

Additional treatments can be applied to augment fabric functionality. For example, moisture-wicking finishes enhance sweat management, while UV protective coatings boost the fabric’s ability to shield wearers from sunlight. These functional finishes maintain the fabric’s natural biodegradability while improving its performance.

Overall, the finishing stage transforms raw corn fiber fabric into a high-quality, market-ready textile that satisfies both eco-conscious values and practical needs.

Garment Manufacturing

With the finished corn fiber fabric ready, the production of complete garments begins. This stage involves transforming rolls of fabric into wearable, stylish clothing through a series of well-coordinated steps in apparel manufacturing.

Cutting:

The fabric rolls are carefully unrolled and cut into specific shapes and sizes according to detailed garment patterns. Precision in cutting is essential to minimize fabric waste and ensure that each piece fits perfectly when assembled.

Sewing and Assembly:

The cut fabric pieces are sewn together using industrial sewing machines. Skilled operators or automated machinery join the pieces with strong and neat seams, maintaining the structural integrity and aesthetic appeal of the garment. Depending on the design, additional techniques like hemming, pleating, or adding darts might be employed to shape the garment properly.

Adding Components:

Garments require additional functional and decorative elements such as zippers, buttons, labels, and tags. These are attached using specialized equipment or handwork to ensure quality and durability. Eco-friendly options for buttons (like those made from recycled materials or natural seeds) and organic labels often accompany sustainable corn fiber garments to maintain the product’s green credentials.

Quality Control:

Before the garments leave the factory, they undergo rigorous quality checks. Inspectors verify the fit, stitching, finish, and overall appearance to meet brand standards and consumer expectations. Special attention is paid to ensuring that the garments comply with eco-certifications and sustainability standards, reinforcing the garment’s identity as an environmentally responsible product.

This manufacturing phase is where innovation meets craftsmanship, resulting in high-quality garments that showcase the potential of corn fiber textiles in the sustainable fashion industry.

Final Garment Features

Garments made from corn fiber bring together sustainability and functionality, offering a range of benefits that appeal to both environmentally conscious consumers and everyday wearers.

Lightweight and Breathable:

Corn fiber fabrics are naturally lightweight, making garments comfortable to wear, especially in warm climates. Their breathability allows air to circulate freely, helping to regulate body temperature and reduce sweating.

Biodegradable:

One of the standout features of corn fiber garments is their biodegradability under industrial composting conditions. Unlike synthetic fibers derived from petroleum, which can persist in the environment for decades, corn fiber textiles break down more rapidly and safely, reducing landfill waste and microplastic pollution.

UV Protective:

Thanks to the inherent properties of the biopolymer, corn fiber fabrics provide effective protection against harmful ultraviolet (UV) rays. This feature makes garments ideal for outdoor activities, combining comfort with health benefits.

Moisture-Wicking:

Corn fiber has excellent moisture management capabilities. It can wick sweat away from the skin to the fabric’s surface, where it evaporates quickly. This keeps the wearer dry and comfortable during physical activity or in humid environments.

Eco-Friendly Fashion Alternative:

Corn fiber garments are often marketed as sustainable fashion products, appealing to consumers who prioritize environmental responsibility. They represent a shift away from fast fashion and synthetic textiles toward circular, plant-based materials that align with global efforts to reduce carbon footprints and promote ethical manufacturing.

Together, these features make corn fiber garments a promising option in the modern apparel market, combining style, performance, and sustainability.

Conclusion

The transformation of corn fiber into finished garments showcases the potential of sustainable innovation within the fashion industry. From harnessing agricultural byproducts to creating biodegradable, high-performance textiles, this process exemplifies how science and craftsmanship can drive eco-friendly alternatives to conventional fabrics.

As consumers become increasingly aware of fashion’s environmental footprint, corn fiber garments offer a compelling solution—combining comfort, functionality, and sustainability. The journey from corn to clothing is not only a technical marvel but also a step toward a greener, more responsible future in apparel manufacturing.

By embracing such materials and processes, the fashion industry can contribute meaningfully to reducing waste, conserving resources, and promoting circular economies—making corn fiber garments a true symbol of modern sustainable style.