When it comes to sewing, the more you practice and perfect your skills, the easier things become. But what seems easy for others becomes a challenge for newbies. Cutting out Continue Reading

Sewing Machine Repair Near Me

A sewing machine whether it is a hand-held traditional or modern sewing machine needs to repair from time to time to get long-lasting uninterrupted service. There are 30 different parts Continue Reading

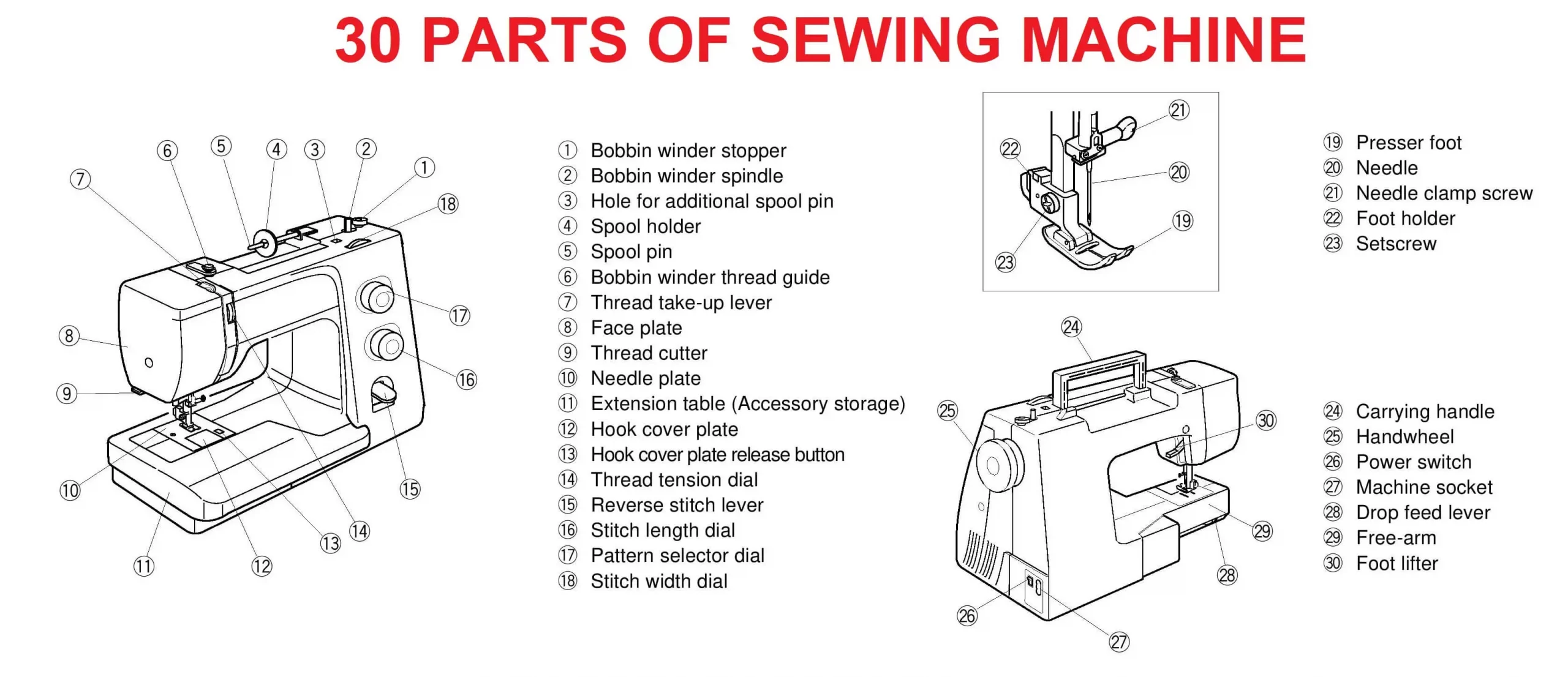

30 Parts of Sewing Machine and Their Functions with Pictures

A sewing machine has several parts which have their own functions. In this article, you will understand the 30 parts of sewing machine and their functions with pictures. Parts of Continue Reading

12 Embroidery Projects for Beginners

The art of embroidery is a centuries-old craft with a rich heritage. Modern clothing can use the same technique that was used in medieval times for decoration. Although embroidery is Continue Reading