The relationship between the NASDAQ 100 and the textile industry represents a groundbreaking shift in the role of technology and Continue Reading

Titanium Dioxide Manufacturing Process Step-by-Step: From Ore to Pigment Production

Titanium dioxide (TiO2) is a white pigment widely utilized in industrial and consumer applications. It is widely used in paints, Continue Reading

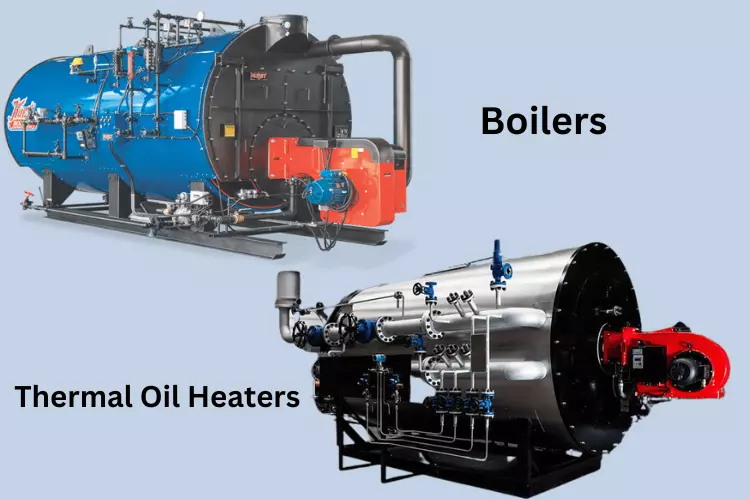

Role of Boilers and Thermal Oil Heaters in the Textile Industry

Introduction The textile industry, a multifaceted sector, relies extensively on intricate processes that demand precise temperature control. In this comprehensive Continue Reading

Stenter Machine Functions: Drying, Width Adjustment, Heat Setting, and More

A stenter machine is a piece of equipment used in the textile industry for processes like finishing, drying, and heat Continue Reading

The Future of Checking Fabric Shrinkage: A New Way to Test

Introduction Understanding fabric shrinkage has been tough in the clothing industry. Measuring how much fabric shrinks after different treatments is Continue Reading

Martindale Abrasion Tester Test Review

The Martindale Abrasion Tester is an essential tool in the textile and fabric industry, used to evaluate various materials’ durability Continue Reading