There is no doubt that clothing makes up the central part of the outfit, but the accessories give a more Continue Reading

An Overview of Textile Machines Used for Textile Manufacturing

In the period of 1760s to sometime between 1820 to 1840 Industrial revolution was the transition to new manufacturing processes. Continue Reading

What is RFT, RFT Factors and Calculation in Apparel Industry

What does Right First Time (RFT) Mean? Right, First Time is lean tools that mean doing the thing right in Continue Reading

Kanban Board in Garments Manufacturing Production Floor

Kanban Board in Garments Manufacturing Production Floor What is Kanban? Kanban is a visual card or billboard; Japanese word which Continue Reading

Management Levels and Their Functions in Textile and Apparel

If you are involved with the apparel industry or you have an interest in working in any level of management, Continue Reading

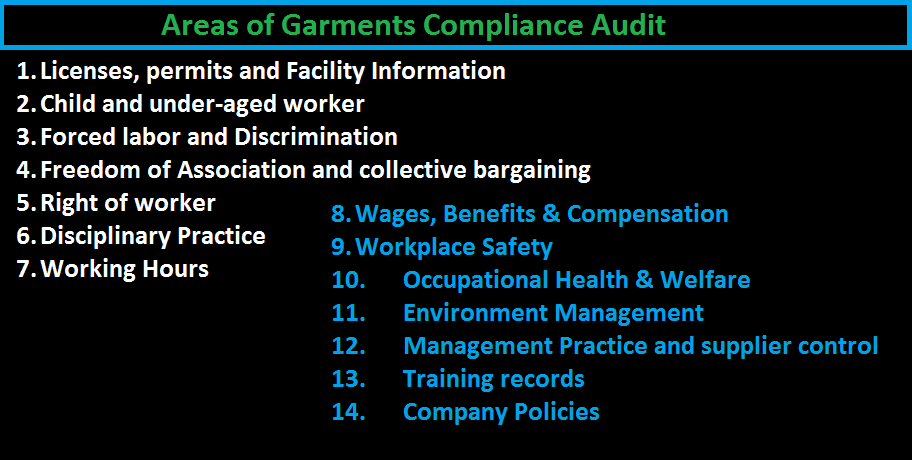

Compliance Audit Checklist in Apparel Industry

Compliance Audit in the Apparel Industry A compliance audit is one kind of audit that is specially designed for auditing Continue Reading