Have you ever noticed your sewing machine acting up? Minor issues can often lead to frustrating problems if not addressed quickly. For Brisbane sewers, one essential component that can wear out over time is the bobbin case. Recognising Continue Reading

Tips to Cut Sewing Patterns on Fabric

When it comes to sewing, the more you practice and perfect your skills, the easier things become. But what seems easy for others becomes a challenge for newbies. Cutting out patterns on fabric is a tricky task for Continue Reading

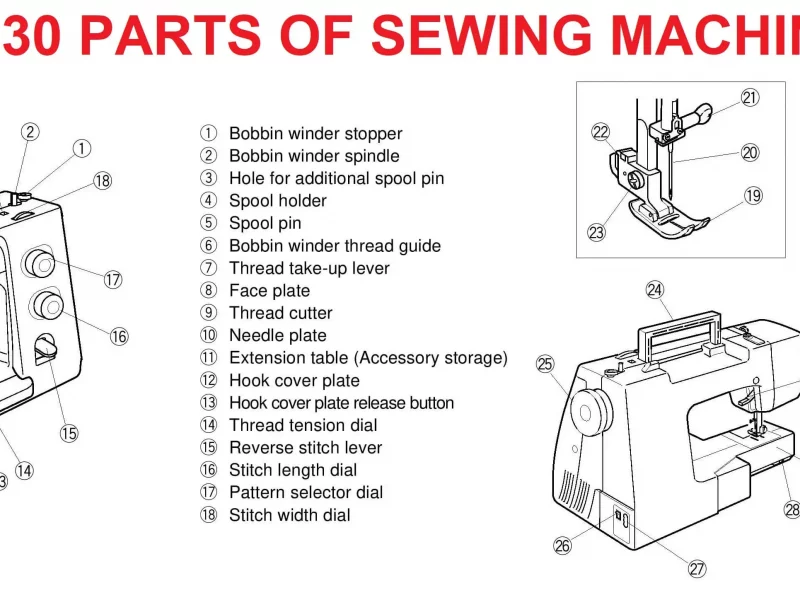

30 Parts of Sewing Machine and Their Functions with Pictures

A sewing machine has several parts which have their own functions. In this article, you will understand the 30 parts of sewing machine and their functions with pictures. Parts of Sewing Machine Functions of Sewing Machine Parts In Continue Reading

12 Embroidery Projects for Beginners

The art of embroidery is a centuries-old craft with a rich heritage. Modern clothing can use the same technique that was used in medieval times for decoration. Although embroidery is easy, you should learn the basics before jumping Continue Reading

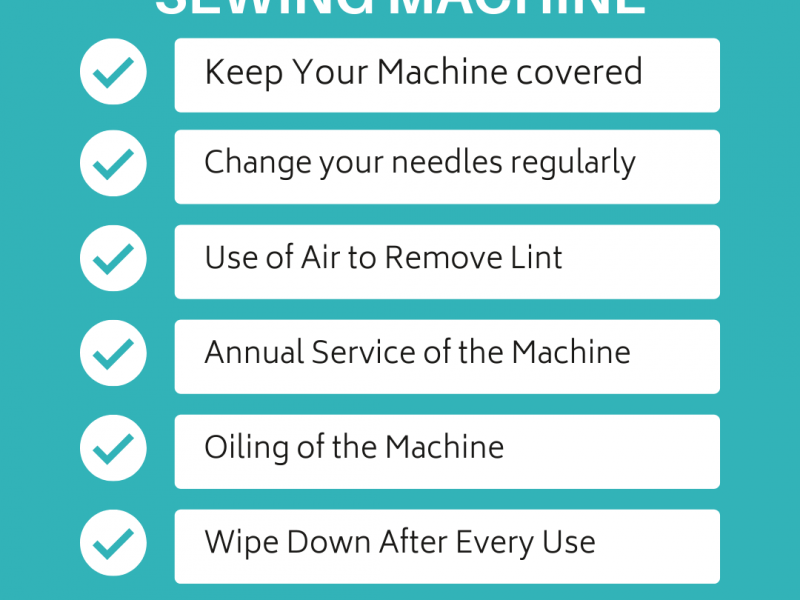

How to Properly Take Care of Your Sewing Machine

For long lasting service of sewing machine, you have to ensure regular maintenance of it. It is not necessary whether you use it regularly or occasionally. In both cases, you should take good care of your sewing machine Continue Reading

8 Ways to Tailored Pants Pockets for Men

Pants without pockets? Not a chance. Pockets are an integral part of your pants or trousers. Pockets are the part of your outfit that would be showing so make sure to get modish pockets tailored. The world is progressing Continue Reading