What is Corn Fiber: Corn fiber is the part of the corn that the body cannot digest. It comes from Continue Reading

How to Use Steam Iron?

Steam irons are ideal for tackling tough wrinkles, especially on fabrics like cotton, linen, and denim. They also add a Continue Reading

What Is Garment Costing and Why Is It Important?

Garment costing is an integral aspect of the fashion and apparel industry, playing a crucial role in the overall business Continue Reading

SOP of Material Control Department

The Material Control Department is a critical department, which is responsible for managing the flow of raw materials and finished Continue Reading

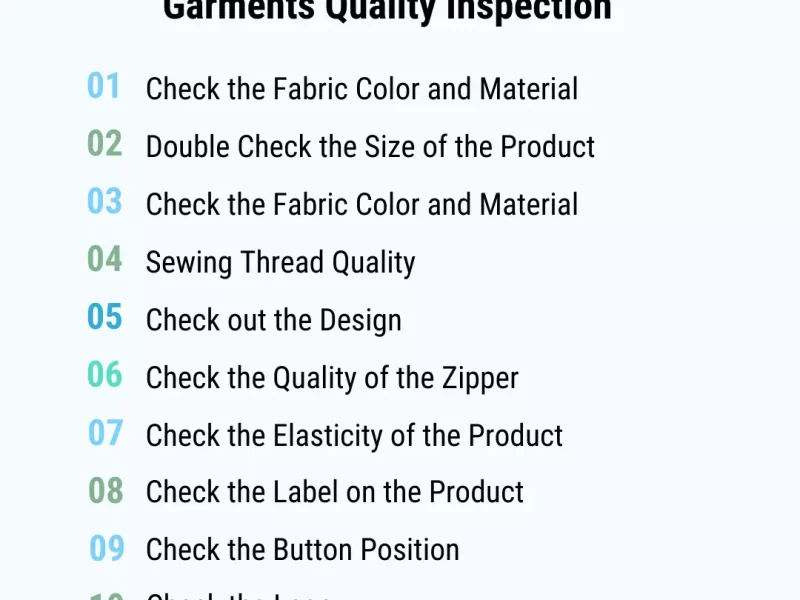

Garment Inspection Checklist

A garment inspection checklist is a list of items that are checked during the quality control process of garment manufacturing. Continue Reading

How to do Garments Quality Inspection

All products manufactured in the garment manufacturing industry must undergo a final inspection and quality check before releasing from the Continue Reading